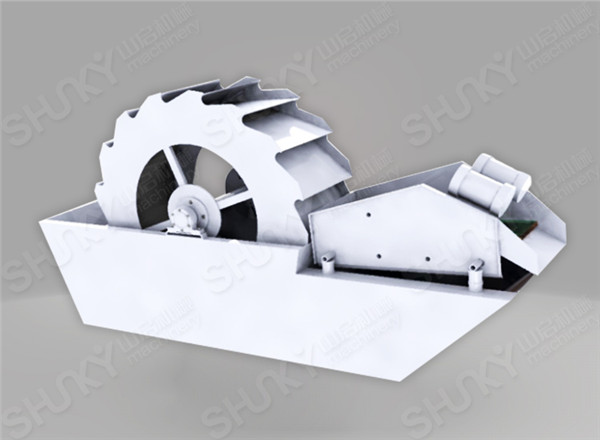

Sand washing recycling machine, as the name suggests, is a combination of the impeller sand washing machine and sand recycling machine, which is commonly used in sand production line for sand washing and recycling. It is much cleaner than similar equipment in sand washing, and sand recycled at a rate of 99%. Sand washing recycling machine of Shanghai Shunky is patented product, and all rights reserved.

At present, there exists a lot of fine sand recycling machine manufacturers on the market, while the quality is not ensured. In order to take leads in the industry and for customers’ benefit, Shunky devoted to researching, finally developing sand washing recycling machine. It improves the quality of sand washing, and the coarse and fine sand is well graded.

Working Principle

1. Structure: the high-pressure separator, dewatering screen, impeller separator, reducer, vacuum pressure pump, cleaning tank, upper cistern, motor, vibration motor and so on.

2. Working process: sand-water mixture goes into the cleaning tank, separated by the impeller separator, and then dehydrated in the lower sieve, while wastewater from cleaning tank (sand, mud, dust and other impurities contained) is transferred to the high pressure separator by high pressure vacuum pump, and then the sand after centrifugal classified is transferred into the dewatering screen through apex. By high-pressure separator, clean tank water, mud, dust and other impurities are into the upper cistern and finally discharged. The finished product is grit in the upper part, while fine sand, or mixed up with coarse sand (adjusted according to customers’ demand) in lower part.

1.Combination of sand washing and recycling, much cleaner than traditional sand washing machine.

2.Low energy consumption, energy saving and environmental friendly.

3.Long lifespan and lower maintenance cost.

4.Simple installation and small volume.

5.Making customerized machine according to different demands.

| Model | Power(kw) | Specification of Separator(mm) | Feeding Size(mm) | Capacity (m3/h) | Water Consumption(m3/h) | Weight(t) | Dimension (mm) |

| LZ26-35 | 23.5 | 350 | ≤10 | 20-50 | 50-80 | 6.18 | 5900×2000×2600 |

| LZ26-55 | 27 | 550 | ≤10 | 30-60 | 60-130 | 6.68 | 5900×2000×2600 |

| LZ30-65 | 37.9 | 650 | ≤10 | 50-120 | 70-150 | 9.3 | 6500×2500×3000 |

| LZ30-75 | 56.4 | 750 | ≤10 | 50-150 | 150-200 | 9.95 | 6500×2500×3000 |